BiSN, a leading provider of permanent downhole sealing solutions, partnered with major operator Sasol in Mozambique to successfully qualify the effectiveness of Wel-lok™ technology for future rigless plug and abandonment and intervention operations. The collaboration aimed to establish the viability of using BiSN alloy via perforations to achieve rock-to-rock sealing and improve abandonment integrity.

“Sasol believed that BiSN alloy is a material which is far less prone to contamination vs traditional cement and can affect a far higher sealing capability within a shorter column height due to its expansion characteristics upon cooling,” said Sandy Ferrari, Well Engineering Consultant at Sasol. “Upon setting, it far exceeded our expectations and we will continue to use BiSN technology in Sasol campaigns.”

Sasol Mozambique faced the challenge of establishing a 62-meter rock-to-rock seal in thin cap rocks, making it challenging to ensure complete sealing using traditional cement. To overcome this challenge, Sasol elected to work with BiSN and a major service provider to deploy BiSN alloy via perforations in 9-5/8″ casing. The objective was to isolate formation activity from a gas-bearing silt layer and create a suitable regional seal within a 10-meter thick shale interval.

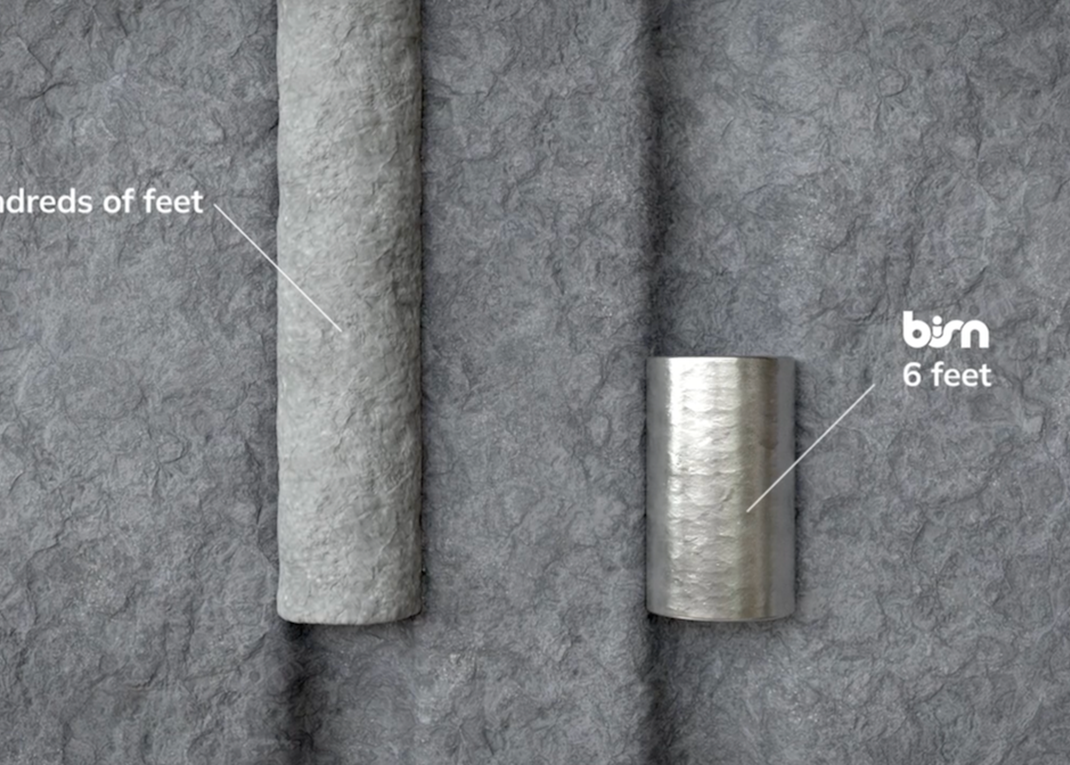

The operation began with the displacement of the 9-5/8″ casing to solids-free brine, followed by casing scraping and perforating gun run on wireline. A cast iron bridge plug was set to provide a mechanical base for the molten alloy, and a 33ft Wel-lok plug was deployed and activated via a timer and hydrostatic switch. The alloy expanded, forming an effective 360-degree circumferential bismuth barrier within the annulus.

“It’s always exciting for BiSN to work with an operator in a new country and see the ever-growing adoption of Wel-lok technology across the industry,” said Paul Carragher, CEO and Founder of BiSN. “The forward-thinking team at Sasol, together with our other partners, made this a smooth and successful operation and we are proud to be working with them on this important initiative in Mozambique.”

Added Benefits for Sasol in the Long Term

The qualification in Mozambique of bismuth alloy for deployment via perforations offers numerous benefits for abandonment integrity and operational efficiency. These benefits include improved long-term abandonment integrity, reduced carbon footprint, reduced operational exposure, and cost savings. The use of BiSN alloy eliminates the need for section milling, reduces rig time, and enables rigless abandonment in the future. It also allows for the abandonment of wells with integrity issues and provides a solution for re-entering wells with gas trapped under shallow barriers.

“A key to success was the excellent collaboration between BiSN and Sasol, from ordering the tools to the successful bismuth alloy installation,” added Klisthenis Dimitriadis, Well Engineering Manager, Sasol. “The openness in communication and transparency on both sides was vital to the deployment’s success.”

About BiSN

Founded in 2010, BiSN’s unique Performance Barrier Technologies allow operators to solve unwanted downhole flow issues once and for all – sealing across the life of the well with confidence to assure uptime, improve production, extend well life, protect the environment and ultimately, to abandon safely.

BiSN provides specialist downhole sealing solutions and services with its patented Wel-lok sealing technology to the global oil and gas industry. BiSN supports its customers from its headquarters in Warrington-England, operations facilities in Houston-Texas, and its growing network of sales and support offices in Aberdeen-Scotland, Abu Dhabi-United Arab Emirates, Calgary-Alberta, Perth-Western Australia, and Macae-Brazil.

For more information, contact:

Colin Wooller, Global Head of Marketing, BiSN

Warrington, England, United Kingdom

T: +44 (0)1928 597 807, M: +44 (0)77487 704 979